While the mashing and distilling process at a bourbon distillery only takes a few days, the aging of the delicate distillate takes years. During those years, the full barrels basically remain untouched and undisturbed — allowing nature to work its magic through temperature and time.

The clear spirit that comes off the still, which is typically called white dog, goes into a new, charred oak barrel, and once it touches the wooden vessel, it officially becomes bourbon. Where that barrel is aged in the warehouse is probably the most important factor to its development, but for the sake of this piece, we’re going to examine how the barrel is aged: vertically or horizontally.

Some American distillers prefer to age their barrels the traditional way — resting on their sides with the bungs up in a rickhouse or rackhouse. And others have discovered a more manageable, less labor-intensive way to store barrels — sitting upright on a pallet that holds four barrels each.

Is one way better than the other? We’ll dig into that here, but both ways of storing and aging barrels are accepted in the industry.

The Traditional Rickhouse

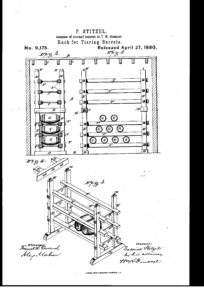

The ricking system of storing barrels on their sides can be traced to a prominent bourbon family from Louisville, Ky. Frederick Stitzel filed a patent on his “rack for tiering barrels” in 1879, and he cited the mechanics of storing barrels like this would be beneficial due to less weight (they were previously stacked on top of each other dunnage-style like in Scotland) and more airflow in between.

Frederick was a distillery owner and member of the legendary Stitzel family. His nephew would later partner with the Weller family to open the successful Stitzel-Weller Distillery, which still runs today and is owned by Diageo.

Throughout the years, rickhouses have been constructed out of everything from wood and brick to metal and concrete. They average about 7-9 stories high and hold thousands of barrels. A smaller rickhouse might hold a few thousand barrels, while some of the larger ones in the industry can hold more than 55,000.

Most rickhouses are not temperature controlled, relying on air circulation and the hot and cold temperatures of the seasons to work their magic on the aging bourbon.

The Palletized Warehouse

Storing barrels vertically on a pallet is a more modern practice in the industry, and it certainly has its benefits. For one, it’s easier to move barrels in and out of a warehouse with the help of a forklift, as opposed to manual labor. It’s also more cost effective and safer.

Pallet racking allows for efficient use of vertical space, which can free up space for storage or more barrels, of course! The pallets used to hold four full barrels of bourbon — which weigh about 520 pounds each — are specially designed for holding heavy loads.

The average palletized warehouse is about four-to-six pallets high, but we’ve heard some, like at Jack Daniel’s, even go up to seven.

One of the main criticisms of palletized warehouses is their lack of airflow between barrels, and there are many industry traditionalists who staunchly prefer the rickhouse storage method because of this.

Of course there are ways to help increase airflow between the pallets — whether that’s spacing the pallets apart, installing fans and blowers, or heat-cycling the warehouse mechanically.

So which is better?

There really is no right or wrong way to store a barrel while it ages, and that decision is an important one for distillery owners. Whether it’s cost, efficiency, tradition or logistics that play into that choice, how barrels age can help influence the overall taste profile of a brand, so it’s definitely not something that is decided hastily.

Some distilleries even use both methods of aging barrels and have various types of rickhouses and warehouses on their grounds. These include Jack Daniel’s, James B. Beam Distilling Co. and Barton 1792, to name a few.

Next time you’re touring a distillery, ask about their preferred way of aging barrels. The opinions and comments on this topic are guaranteed to be interesting and endless.